Qingdao Xingzhicheng Hardware Spring Co., Ltd. is located in Qiandongcheng Industrial Zone, Jimo District, Qingdao City.

It is a company engaged in the development, design and manufacture of precision springs, shrapnel, spring pins and precision shafts for many years.

Use imported computer equipment and raw materials for manufacturing and processing.

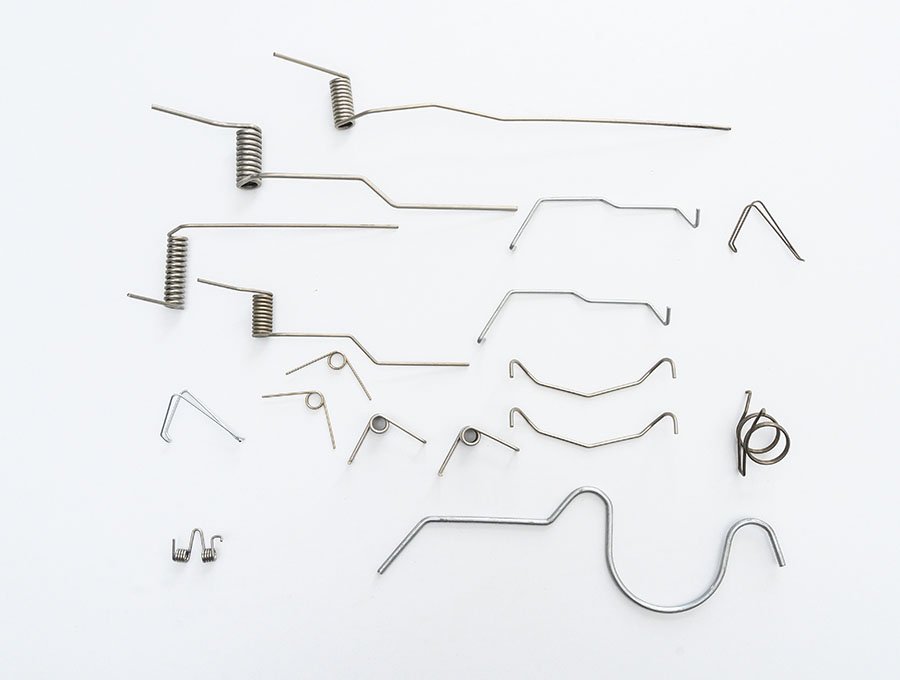

Product description :

Compression springs, tension springs, torsion springs, special-shaped springs, touch springs and metal shrapnel, etc.; manufacturing electronics, electrical appliances, switches, toys, office supplies, daily necessities and precision springs for information and transportation: processing wire diameter: 0.2~30.00mm .

Materials used:

Stainless steel wire, carbon steel wire, phosphor bronze wire, galvanized wire, nickel-plated wire and various imported materials and special materials.